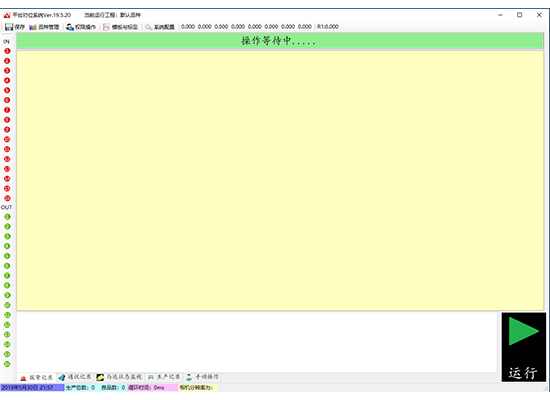

System configurations

● Integrated Controller : SI200

● Remote IO: 86 points

● Vision alignment system

Core technologies

● The solution uses closed-loop controllsystem, pure PC control, and EtherCAT bus, with vision platform positioning. Deep integration of different functional modules to achieve fast correspondence and efficient completion of PCB board exposure alignment action.

● EtherCAT network bus controls technology, and one industrial PC can realize motion control and image processing.Space saving and high maintainability.

● Due to the low mechanical positioning, it cannot adapt to the production of high-precision PCB. Using visual alignmentcan meet the precision requirements of PCB, and realize the μ-level capture and alignment.